Visit the Nanosital website direct for detailed information and available colors.

Nanosital by RusGems

ABOUT OUR INVENTORY

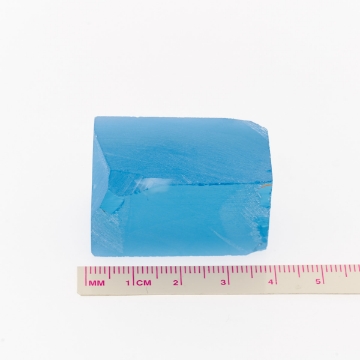

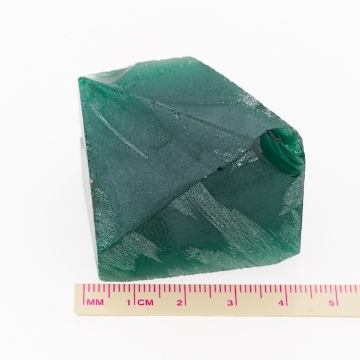

We purchase large parcels directly from RusGems Nanosital in Thailand. We then slab saw the material into manageable sizes.

This material is all clean of visual defects and is very consistent in color saturation so color zoning is not an issue.

PLEASE DO NOT HESITATE TO INQUIRE OF A COLOR NOT LISTED HERE FOR SALE

We may have available just not listed at the time of your visit

OUR EXPERIENCE IN FACETING NANOSITAL

Orientation is not an issue as this is a ceramic glass with a higher refractive index and a hardness of 7 (moh) similar to natural quartz and other natural gemstones.

In cutting and polishing, standard faceting tools are required. Start with a 260 diamond for roughing (pre-forming), followed by 600 diamond, 3000 diamond pre-polish onto 50k-60k final diamond polish.

I have found Nanosital to be very easy to work with, polishing comes very quick with diamond media.

MANUFACTURING

Nanosital is manufactured at RusGems factory near Moscow, Russia, on patented technology.

SAFETY

Nanosital does not contain any health hazardous contaminants (lead, arsenum, cadmium, etc.).

TECHNOLOGY

Nanosital is an optically transparent polycrystalline material that is formed by the crystallization of glass with corresponding chemical composition and has higher physical and chemical properties than the original glass.

Nanosital is one of the glass-ceramic materials, which are known for more than 50 years and have a wide range of compositions and applications. RusGems has adapted existing technology to create a material specifically optimized for jewelry. As a result of a multi-component high-temperature composition on the base of two main oxides – SiO2 and Al2O3 – was obtained. It is well-known that the above-mentioned oxides are key components of most natural gemstones. The rest of nanosital's components are picked to approximate the maximum required optical characteristics as well as density and hardness. Our technology allows us to vary components of composition quite widely. As a result, nanosital that is absolutely identical to its natural counterpart can be produced each time.

PHYSICAL AND OPTICAL PROPERTIES

Nanosital is synthesized at a temperature of 1700 °C. The table above presents its main properties in comparison to well-known materials:

Chart of physical and optical properties

| PHYSICAL PROPERTIES | NANOSITAL |

|---|

| Mohs hardness scale |

7 |

| Refractive index |

1.65 – 1.7 |

| Specific gravity |

3.5 - 4 |

| Dispersion (play of colors) |

0.015 |

| Melting point, °C |

1700 |

| Treatment problems |

Can be readily polished on a diamond polishing wheel 3/2 |

| Heat color stability (in lost-wax casting) |

yes |

Main characteristics of Nanosital

- Nanosital's specific gravity index is very close to that of the most valuable gemstones such as topaz, sapphire, ruby and aquamarine.

- Nanosital and the optical properties of the most popular color gemstones are almost similar. Nanosital's main feature is its lack of an unnaturally strong luster, which is typical of cubic zirconia, wherein the play of colors remains attractive.

- Nanosital's hardness (7 on Mohs scale) guarantees jewelry durability without the loss of its original look. The Nanosital hardness index (7) is higher than glass (5), but lower than one of the hardest materials – corundum (9).

- Its high melting point allows the use of any colored Nanosital in lost-wax casting.

- Color and transparency. Its wide color range, full correspondence to natural analogue, perfect optical properties, total transparency, and absence of inner defects makes Nanosital the best, readily available rough jewelry material on the market.